Client: NI Water, Castor Bay

NI Water, Utilising Waste Heat in Castor Bay Low Lift Pump Control Room

GSHP Case Studies

NI Water, Utilising Waste Heat in Castor Bay Low Lift Pump Control Room

Solar PV, GSHP, Underfloor Heating, MHRV

Objective:

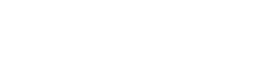

b4b Renewables was tasked with finding an environmentally sustainable solution to help NI Water at Castor Bay, Lurgan, manage and utilise the excess heat in their pump control room, where temperatures regularly exceed 30°C.

NI Water wanted to stop venting this heat to the outside of the building and instead find an innovative way to use the thermal energy generated by the pumps.

The solution had to provide heating to nearby staff offices. Additionally, NI Water had an oversized, inefficient oil burner for heating and hot water, which was costly to operate. The goal was to reduce the reliance on this oil burner or enable a reduction in its size, together with reducing the CO2 emissions overall.

Challenge:

The challenge was to reduce the circulation of 30°C heat within the Process Control Room and prevent its extraction into the atmosphere. This in turn would help to increase the lifetime of the equipment in the room which will have a longer life span when operating at lower temperatures.

The aim was to recycle this heat to power radiators in the offices on the building’s first floor.

This required a system that could convert the hot air from the plant room into usable hot water. b4b Renewables needed to eliminate the need for the oversized and costly oil burner, while efficiently managing the heat within the building.

Solution:

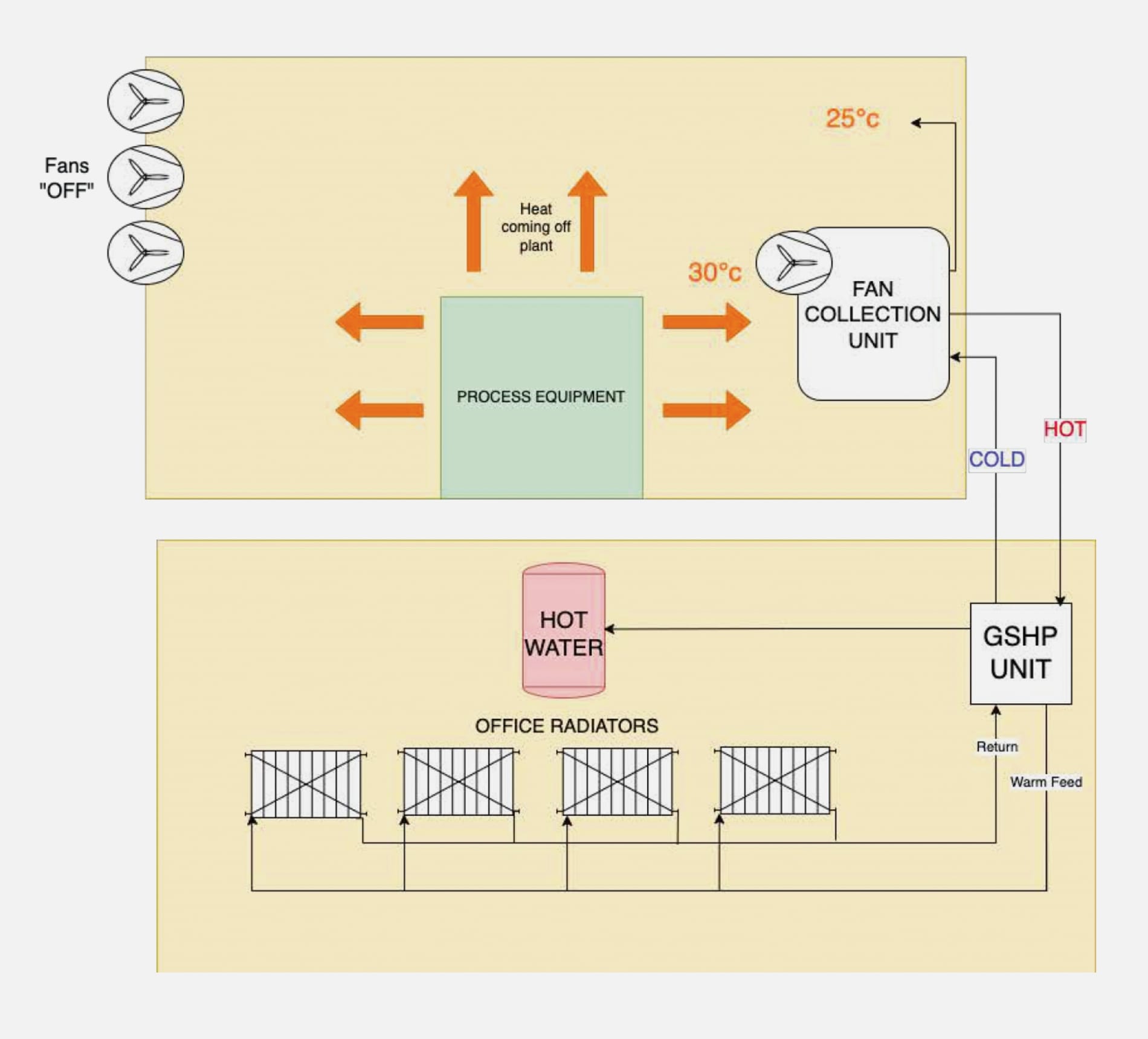

b4b Renewables installed a Geothermal Ground Source Heat Pump system, which focused on reducing the temperature in the pump control room to a comfortable 20-25°C using a fan collection unit.

This solution not only stopped hot air from being vented outside but also converted it into usable hot water for radiators throughout the building.

By leveraging the heat from the plant room, the heat pump eliminated the need for any traditional heating methods, including air conditioning and the oversized oil burner. As a result, NI Water now benefits from consistent room temperatures in their office space all while utilising heat that would have otherwise gone to waste. This solution has significantly reduced operational costs and contributed to lowering NI Water’s carbon footprint. b4b Renewables also carried out a chemical flush of the existing radiator system before the new system was installed.

Key System requirements

- Ecoforest GSHP rated at 22kW heat output

- Indoor AU22 heat pump indoor fan unit (defrosting and weather compensation built in)

- Indoor Unit Measurements: 1060mm H x 600mm W x 710mm D. Outdoor Unit Measurements: 900mm H x 1800mm W x 600mm D.

Related Case Studies

Solar Delivers Fast ROI for RE:SURE, Cookstown

Based in Cookstown, Co. Tyrone, RE:SURE wanted to reduce their dependency on the electricity grid, cut operational costs, and boost energy efficiency...